The consistent reduction of production waste is driven by targeted planning, technical optimization, and employee expertise at Podanfol.

A key approach is the careful grouping of orders by colors and film types. This optimizes material usage, reduces unused components, and makes the overall production process more efficient. Planned and cyclical machine maintenance minimizes machine downtime and prevents unnecessary material loss.

Employee training and awareness also play an important role: workshops and further education highlight the importance of correct machine operation, enabling more precise use of raw materials and significantly reducing waste.

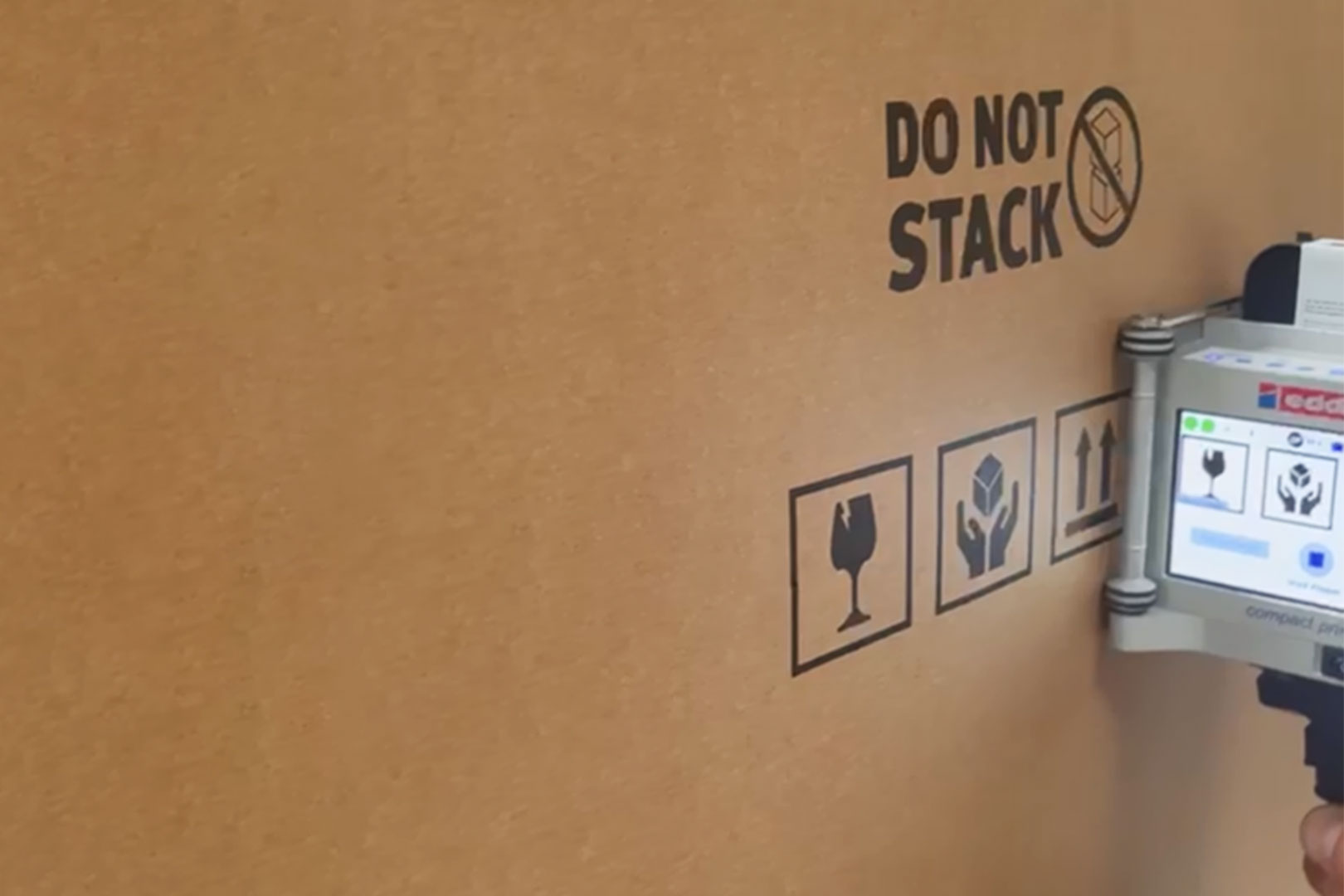

The automation of quality control using modern image processing systems not only improves production quality but also reduces environmental impact by minimizing defective products and optimizing material usage.

Through these coordinated measures, production waste is sustainably avoided while valuable resources are preserved.